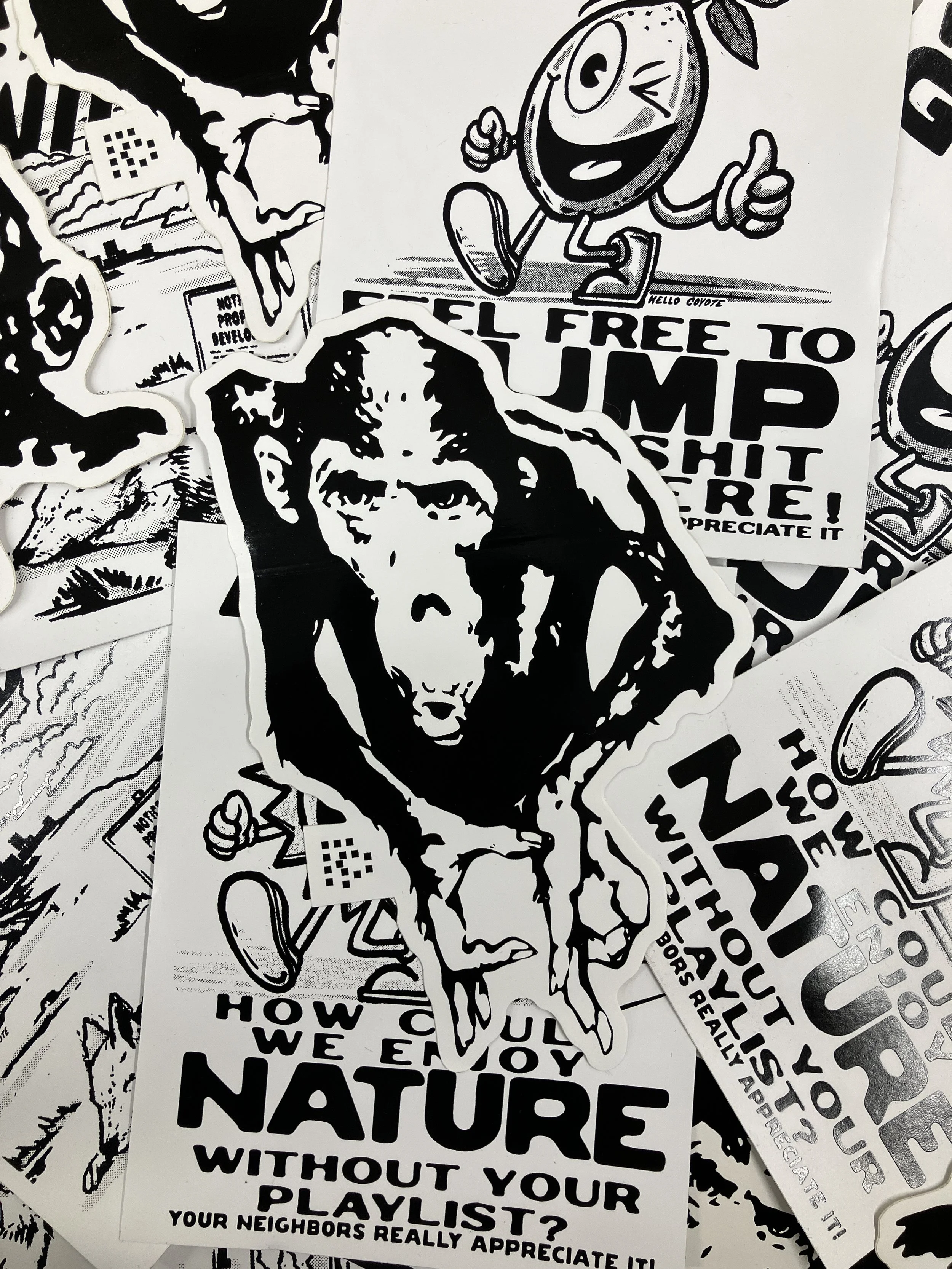

STICKERS

Santa Barbara STICKER SERVICES

Whether you’re building a brand, promoting an event, or creating retail-ready merchandise, custom stickers remain one of the most versatile and cost-effective marketing tools available.

Foundation Press sources premium custom stickers through industry-leading manufacturing partners while managing the entire production process in-house — from artwork setup to proofing and delivery.

You get high-end sticker production without having to navigate the technical side yourself.

Our STICKER PROCESS

1. Artwork Review

File setup optimized for your print method.

2. Material & Finish Selection

Vinyl type, lamination, specialty effects.

3. Proofing

Digital proofs for approval.

4. Manufacturing

Produced through vetted partners.

5. Delivery

Shipped direct or bundled with apparel orders.

F O U N D A T I O N P R E S S L O V E S Y O U

. . : : : . .

F O U N D A T I O N P R E S S L O V E S Y O U . . : : : . .

Sticker Printing Methods

Silkscreen Stickers

The Gold Standard of Sticker Printing

Silkscreen sticker printing is a time-tested process where each ink color is printed individually using UV-cured inks layered onto premium vinyl.

The result is a sticker with noticeably thicker ink, deeper color saturation, and unmatched outdoor durability.

Why Choose Silkscreen?

Ultra-Vibrant Color

Ink is layered significantly thicker than digital printing, producing richer, more saturated tones.

Embossed / Textured Feel

Layered ink creates a raised surface you can physically feel.

Extreme Durability

Weatherproof, dishwasher-safe, and built for long-term outdoor exposure.

High-Gloss UV Protection

Multiple clear coats protect against fading, abrasion, and moisture.

Best For

Retail merchandise

Artists & illustrators

Outdoor brands

Skate / surf / snow industries

Long-term applications

Minimum: 250 pieces

Turnaround: ~2–3 weeks

Digital Stickers

Fast, Flexible, and Cost-Efficient

Digital sticker printing uses high-resolution CMYK processes to produce full-color designs quickly and affordably.

It’s the ideal option for short runs and fast deadlines.

Why Choose Digital?

Quick Turnaround

Perfect for events, launches, and tight timelines.

Full-Color Printing

Great for gradients, photos, and complex artwork.

Precision Die-Cutting

Custom shapes included without additional tooling.

Outdoor Safe

Durable and dishwasher safe, though not as long-lasting as silkscreen.

Best For

Events & giveaways

Trade shows

Promotional campaigns

Short-run merch

Minimum: 50 pieces

Turnaround: ~3–5 business days

Silkscreen vs. Digital Stickers

Both sticker methods serve different purposes — the right choice depends on how your stickers will be used, how fast you need them, and the level of finish you’re after.

Silkscreen Stickers

Built for longevity and visual impact

Silkscreen printing applies real ink in layered passes, creating deeper saturation and a tactile surface you can actually feel. Because the ink sits heavier on the material and is sealed with protective coatings, these stickers are engineered for long-term outdoor use and premium retail applications.

They’re ideal when durability, texture, and color richness matter most — especially for brands treating stickers as merchandise, not just handouts.

Best suited for:

Retail & resale merch

Artist editions

Outdoor brands

Equipment & vehicle applications

Long-term promotional use

Digital Stickers

Fast production with full-color flexibility

Digital printing uses high-resolution CMYK processes to reproduce detailed artwork quickly and efficiently. This method excels with gradients, photographic imagery, and complex color blends while keeping production timelines short.

If speed, lower minimums, or budget flexibility are priorities, digital stickers are a strong solution.

Best suited for:

Events & giveaways

Trade shows

Short-run promotions

Product packaging

Fast-turn campaigns

How to Decide

If your goal is to create a sticker that feels like a product — something collectible, retail-ready, and built to last — silkscreen is the clear winner.

If you need high-quality stickers produced quickly for marketing, launches, or short-term use, digital printing gets the job done efficiently.

Not sure which direction to go? That’s where we come in — we’ll review your artwork, timeline, and budget to recommend the best production route.

Waterproof & Weatherproof Performance

Our premium outdoor stickers are built to withstand demanding environments.

Key durability features include:

UV-protective clear coatings

Aggressive permanent adhesive

Fade resistance

Scratch resistance

Moisture protection

When applied to a clean, dry surface, these stickers hold up against:

Vehicles & boats

Equipment & machinery

Outdoor venues

Snow & surf environments

Outdoor lifespan typically ranges 3–5+ years depending on exposure.

Adhesive Performance

We source stickers using high-performance permanent adhesives engineered for long-term bonding.

Adhesion curing timeline:

First 24 hrs → ~50% bond

72 hrs → ~75% bond

1 week → Full adhesion

Once cured, removal requires tools and solvent cleaning.

Color & Sunlight Exposure

All printed materials experience some degree of fading over extended UV exposure — including vehicles and signage.

However, premium silkscreen production significantly slows this process through:

Thick ink layering

UV-resistant coatings

High-grade pigment inks

This results in longer-lasting color compared to standard digital prints.

Specialty Sticker Options

Looking for something beyond standard vinyl?

We offer a range of specialty finishes:

Holographic

Glitter

Reflective

Gold & Silver foil

Matte coatings

Static cling

Minimum: 50 pieces

Turnaround: ~3–5 business days